It was sunny and plus thirteen for about 90 minutes earlier today, so I popped out to the wood shop and dashed some Walnut coloured Danish Oil Stain onto my youngest daughters new single bed frame for the cottage.

I started by spot sanding a few bits that didn’t get all the love they needed the first couple of go rounds, and then spent a few minutes dusting it off with the air compressor. Then I splish-splashed the Danish Oil rub on it with a very wet foam brush, and ran through a few clean rags wiping it off. I think I managed to avoid runs in the finish, but I’m sure there’s one someplace very visible that I couldn’t see while I was bustling away this AM.

Good thing it’s so light weight, I didn’t need to call for help to move the whole thing around while I worked. Rests on my bench easily enough. It’s times like these that I am thankful for all the space saving theatrics I’ve had to undertake recently. My old layout would never have been wide or clear enough for both the frame and me. No chance I could have freely walked all 360 degrees around it before. I could still do with the whole shop being a good 36 inches wider, but that’s a very expensive construction matter. Also not going to happen. No way I tear down walls, and add roof for just three feet. Plus the property line is right there and no municipal office would ever grant me permits to get closer than eight feet to the line. So I’ll do what I can with what I’ve got.

Side bar: I am toying with the idea of taking down the pre-built racking that looks kinda shifty, in favour of metal racks, and reclaiming higher up wall space, but I need to get rid of several stored doors, and car seats, strollers, and household junk before I do that. It needs careful planning. I could benefit a great deal from doing so, but it’ll cost me both time & money, and a fair bit of aggravation to boot. I’m thinking it over. But I digress.

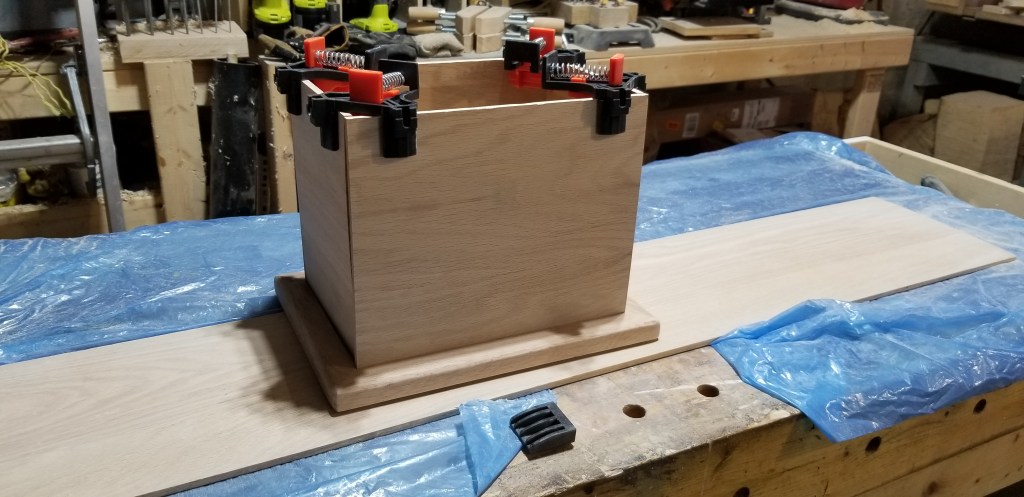

The Pine bed frame is one inch thick, with box joints, and a slatted cross member design. The feet all screw on, and the slats screw down into their mortises for extra peace of mind. It’s light weight, and has been stained to a Walnut brownish tone. One single pass. I’m told with Danish Oil I could do multiples, but I find one wetly soaked coat works fine for me. It ain’t no heirloom quality piece but it should last a few years. I hope.

Finishing isn’t exactly my favourite thing to do. It’s sticky, and smelly, and finicky too. My shop doesn’t have an air cleaner, nor do I use anything better than a shop vac to control the dust I make. Not good for high end, ultra high quality finishing. But I get it done regardless. Although now the temperature has plummeted down to minus one, and will go even lower and bring in some snow too. So I don’t know how anybody can plan around this type of thing. Well… a temperature controlled working space would alleviate those stressors, but I ain’t got that kinda dough just lying around for a quirk of mine.

So maybe a single spray on layer of Diamond Coat will go on next, or not. This piece may not be worth the additional effort. It will get scratched & marred. I’m none too concerned about that. If I can get a shot of it in situ up north I’ll update about the bed frame one last time. Take care out there. Ciao Bella.

You must be logged in to post a comment.